Interested in Excavating?

Get Excavating articles, news and videos right in your inbox! Sign up now.

Excavating + Get AlertsWhat do you look for when purchasing an equipment trailer? Durability? Finish? Brakes? Hitch? Perhaps it’s the decking or ease of operation? Better yet, what should you be looking at before you buy?

Here are some points to consider from those in the know:

Frame

Can’t decide between a gooseneck or a bumper pull trailer? You might start with the frame. “When you’re looking to buy a gooseneck flatbed, it’s important to look at the I-beam used for the main frame,” says Ronnie Enns, general manager for Happy Trailer Sales in Sumner, Texas, manufacturer of PJ brand trailers. “The industry standard is a 12-inch I-beam, but higher-quality trailers will feature a 19-pound-per-inch I-beam versus 16 pounds per inch.” Another important consideration is crossmember spacing, he says. “For most trailers, 16-inch centers are sufficient, but upgrading to 12-inch centers becomes necessary when hauling more weight.”

Axles

The size and type of axle determine the trailer’s hauling capacity, or gross vehicle weight rating (GVWR) – the combination of trailer and cargo. “Most gooseneck flatbeds are equipped with tandem 10,000-pound axles and dual wheels; however, 12,000-pound axles are a popular upgrade,” Enns says. “The first step in deciding what size axles you need is determining how much weight you will haul.” And make sure the VIN number with the GVWR is clearly visible, says Ed Steinemann, sales coordinator for Felling Trailers in Sauk Centre, Minn. “That’s the first thing the DOT is going to look for when you go through a scale. The VIN tag will tell you how much weight you can put on the trailer without overloading it.”

Wiring and lights

Another important item is wiring. Steinemann recommends LED lights and an enclosed wiring harness. “If you don’t have enclosed wiring, moisture is going to get in,” he says. That can lead to rust and headaches down the road. Modern LED lighting also offers numerous advantages over incandescent bulbs, including lifetime service, better illumination and less power draw.

Finish

Steinemann says preparation, rather than final coating, is the most important consideration when it comes to the trailer’s finish. “What we do is metal-grit blast our steel, which cleans the inside of the pores. Then we wash it and give it two undercoats and three overcoats.” Felling uses Hentzen Coatings. The paint products consist of a two-component urethane technology.

Durability

Timothy Davis of Branchland, W.Va., puts durability at the top of his list of trailer features. “I always try to look for something heavy-duty, or a little extra heavy-duty than what I want to haul,” says the owner of TR Davis, a septic system installation and excavation company. “It should be able to handle the load for a long period of time,” he says. The owner of 10-ton, 5-ton and 1-ton trailers also opts for air brakes. “It’s about as dependable a system you can buy.” LED lighting and pintle hitches are two other selling points for Davis, whose equipment fleet includes a John Deere 310E backhoe, 450G dozer, Kubota U45 tracked mini-excavator and tandem-wheel International dump truck. Currently in the market for a new trailer, Davis says he’s not looking at a particular brand, but he’d like to have something with a tilt deck. “It’s easier on your back,” he says. Avery Zahn of Worthing, S.D., also puts durability at the top of his list. “Axles are big. That goes with the durability,” says the owner of Infra-Track, a jetting, hydroexcavating and sewer televising company. “Heavy-duty frame, closer channeling – that’s kind of a big deal,” he says, along with heavy-duty axles.

Rustproofing

Living in Annandale, Minn., Dean Flygare, owner of Flygare Excavating, puts a premium on paint and/or rustproofing. “That seems to be the biggest issue we have with our trailers,” he says. “The salt and road grime just eats trailers alive. I want to see that it’s powder coated, but even that eventually doesn’t hold up. A lot of our trailers we get rustproofed or undercoated from the manufacturer, or we do it ourselves. That to me is the biggest thing we look for. The only other thing would be ramps, depending on the kind of trailer – the ease of loading and unloading.”

Brakes and hitches

Flygare has a 25-ton, a 30-ton and several skid-loader trailers. “As far as the bigger trailers, air brakes are less maintenance and much more reliable than electric,” he says. “We try to go with air whenever we can.” Flygare also has pintle hitches on all his trailers – both for convenience and security. “We have the pintle hitches on the back of our dump trucks and use pintle adapters for our pickups and smaller trucks. It simplifies things,” he says. “The other thing is there aren’t a lot of people who have a pintle hook on the back of their pickup that can take off and steal my trailer.”

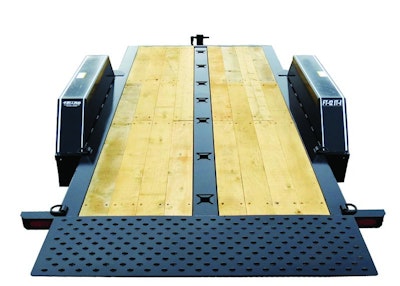

Decking

Oak decking is another feature Flygare looks for in the trailers he buys. “We tried rubber lumber just for grip, but it didn’t turn out so good. The trailer was built for lumber, so it didn’t have enough cross support; the rubber was a little more flexible. In between the cross-braces it would flex and pull the bolts,” he says. “If you had a trailer built for that material with extra bracing, it probably would be great, but it didn’t work out in our case.” Flygare always buys new trailers, primarily for peace of mind. “With the corrosion and rust, even with a new trailer, after a number of years it really eats them up. It just seems best to start with something fresh,” he says. “With a used trailer, you don’t know how it was taken care of or if it was ever rustproofed.”