Interested in Trucks?

Get Trucks articles, news and videos right in your inbox! Sign up now.

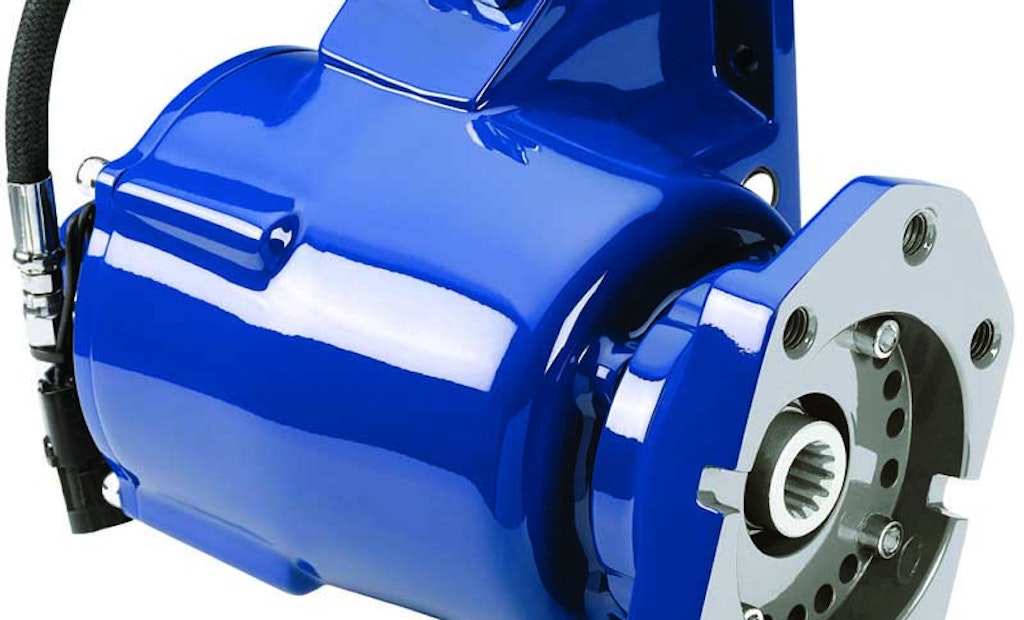

Trucks + Get AlertsThe world of power take-offs, or PTOs, continues to see a growing trend toward automatic transmissions in the work truck industry. While not yet 50-50, it’s getting close, says Dave Douglass, director of training and education, Muncie Power Products.

“On a manual transmission, you have PTOs that are mechanically shifted,” Douglass says. “It could be a cable shift or an air shift. You have PTOs that are engaged by gears sliding in and out. In the case of automatic transmissions, you have PTOs that are engaged by hydraulic pressure from the transmission that acts on a piston to engage a clutch pack. Those kinds of PTOs are commonly referred to as clutch-shifted PTOs.”

The advantage of the clutch-shifted PTOs for a vacuum truck operator is the elimination of gear clash. In some cases, the PTO can also be engaged before the truck reaches a full stop.

“Currently, the pneumatic blower industry is not switching over to automatic transmissions,” Douglass says. “That will probably come, but right now that’s still a segment of the market dominated by manual transmissions. In the vacuum truck market, there’s a mix of manuals and automatics. The larger vehicles — the Class 7s and Class 8s — are still predominately manual, although there are some automatics in the smaller Class 4 and 5 trucks. Automatics have made an impact there.”

SELECTION

When matching a PTO to a transmission, it’s critical to make sure you have the complete make and model number of the transmission, including any prefixes or suffixes.

“Those things can make a difference in PTO performance,” Douglass says.

You’ll also want to make sure the input rotation of the pump matches the rotation of the PTO. Another thing, critical in the case of blowers and vacuum pumps, is to make sure the PTO can transmit the necessary torque and horsepower required to run your equipment.

Since blowers rely on high torque and high speed, PTO selection is critical. With vacuum pumps, selection often comes down to the size of the truck and the pump.

When evaluating torque ratings, it’s important to determine if the driven equipment will be performing continuous- or intermittent-duty applications. A rating higher than the actual required torque will be necessary if the driven equipment is performing continuous duty. To determine torque rating, multiply the horsepower requirement of the driven equipment by the engineering constant of 5,252 and divide by pump input rpm.

INSTALL THE PTO

Once you’ve selected the correct PTO, it’s time to focus on installation and maintenance.

When mounting the PTO to the transmission, you typically have two options. In the case of manual transmissions, there’s a six-bolt aperture on the right or curb side of the vehicle and an eight-bolt aperture on the bottom of the transmission offset to the left. Automatic transmissions have two 10-bolt apertures, one on each side. Accessibility is the primary determiner of which aperture is used.

“With manual transmissions, the eight-bolt aperture on the bottom of the transmission can typically be used to mount larger PTOs, as opposed to the six-bolt opening on the right side,” Douglass says. “Usually, on a manual transmission, you’ll use the PTO on the bottom eight-bolt aperture because it can handle more horsepower and torque.”

Many truck manufacturers have also eliminated the right-side option by mounting exhaust systems in that area, leaving only the bottom or left side of the transmission for mounting the PTO.

Backlash between the mating gear of the manual transmission and the PTO is determined by adding or subtracting gaskets to achieve a backlash between 0.006 and 0.12 inches, while backlash in automatic transmissions is determined by the transmission manufacturer and the single supplied gasket.

MAINTAIN IT SAFELY

Primarily installed by upfitters, the hardworking PTO requires little maintenance beyond periodic checks of the mounting bolts for proper torque and the shaft seal for evidence of wear.

Where the PTO is supplying hydraulic flow to drive a vacuum pump, it’s important to keep the spline coupling between the pump and the power take-off lubricated. Some manufacturers offer a wet spline that lubricates the cavity between the pump and PTO.

“There’s really not much maintenance to a power take-off,” Douglass says. “And if you would have called me 20 years ago, we’d be talking about just manual transmissions, and it probably would have been the same answer. PTOs aren’t traditionally high maintenance.”

It’s always a best practice to put safety first when working around equipment. And never inspect a PTO with the truck running. “We always say the best place for the keys if someone is going to be under a vehicle is in that person’s pocket,” Douglass says.

“And if you’re doing maintenance on the hydraulic system, make sure the pressure is relieved before loosening any couplings. Never look for a hydraulic leak by running your hand along the hose or any of the fittings or couplings,” he says. “Hydraulic oil systems can carry up to 3,000 psi and can result in a serious oil injection injury.”

Always put safety first.