Interested in Education/Training?

Get Education/Training articles, news and videos right in your inbox! Sign up now.

Education/Training + Get AlertsTSS is the most common measure of the amount of solids, both organic and inorganic, in wastewater effluent. Raw wastewater has a TSS typically ranging from 155 to 330 mg/L, with 250 mg/L being typical concentration. After going through primary treatment in a septic tank, a typical TSS value is less than 65 mg/L. After secondary treatment in an advanced treatment system, the TSS will normally be below 25 mg/L.

Biochemical oxygen demand and TSS together measure the strength of the wastewater. They can serve as an indicator of system performance. The organic loading rate of a system is the number of pounds or kilograms of BOD per day and the “solids loading rate” — the number of pounds or kilograms of TSS per day — are common mass loading rates.

TSS is the measure of all suspended solids in a liquid. It is measured by filtering a well-mixed sample through a standard glass fiber filter and drying the residue retained on the filter at 217 to 221 degrees F (103 to 105 degrees C). The increase in the weight of the filter represents the amount of total suspended solids.

TSS is the measure of all suspended solids in a liquid. It is measured by filtering a well-mixed sample through a standard glass fiber filter and drying the residue retained on the filter at 217 to 221 degrees F (103 to 105 degrees C). The increase in the weight of the filter represents the amount of total suspended solids.

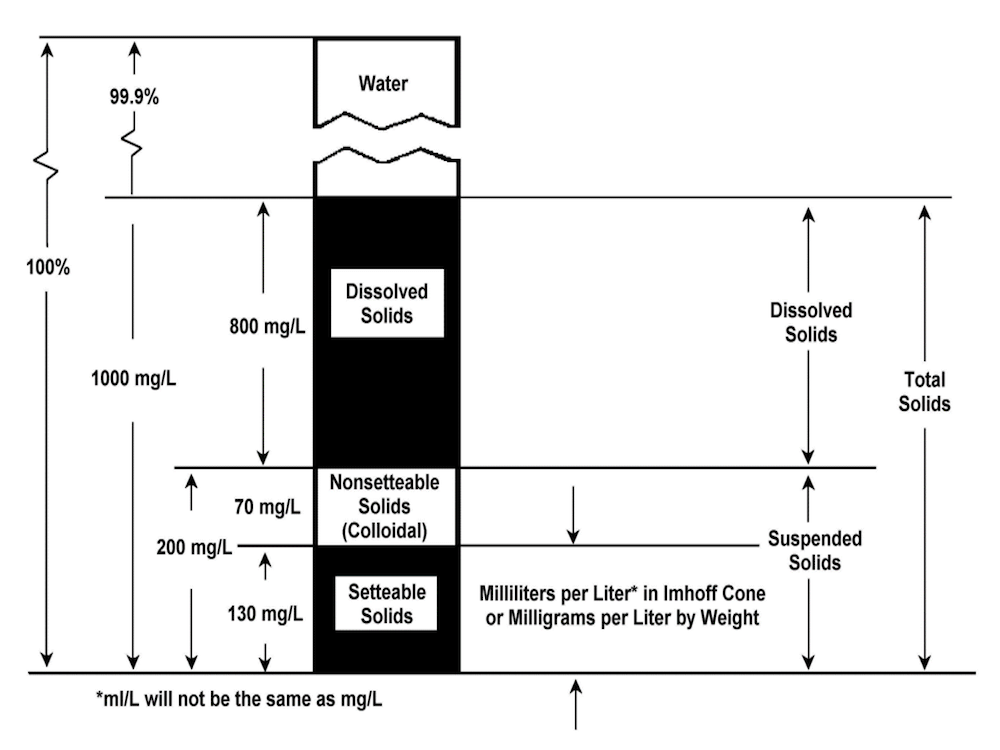

Other terms and measurements of solids in wastewater treatment systems are listed below:

- Solids, settleable: Suspended solids that will settle out of suspension within a specified period of time.

- Solids, total (TS): Mineral, cells, etc. that are left in wastewater after evaporation of the water fraction at 103 degrees C.

- Solids, total dissolved (TDS): Material that passes a standard glass fiber filter and remains after evaporation at 103 degrees C.

- Solids, volatile: Weight loss on ignition of total solids — not distinguishing between inorganic and organic matter and including loss due to decomposition or volatilization of some mineral salts at 550 degrees C.

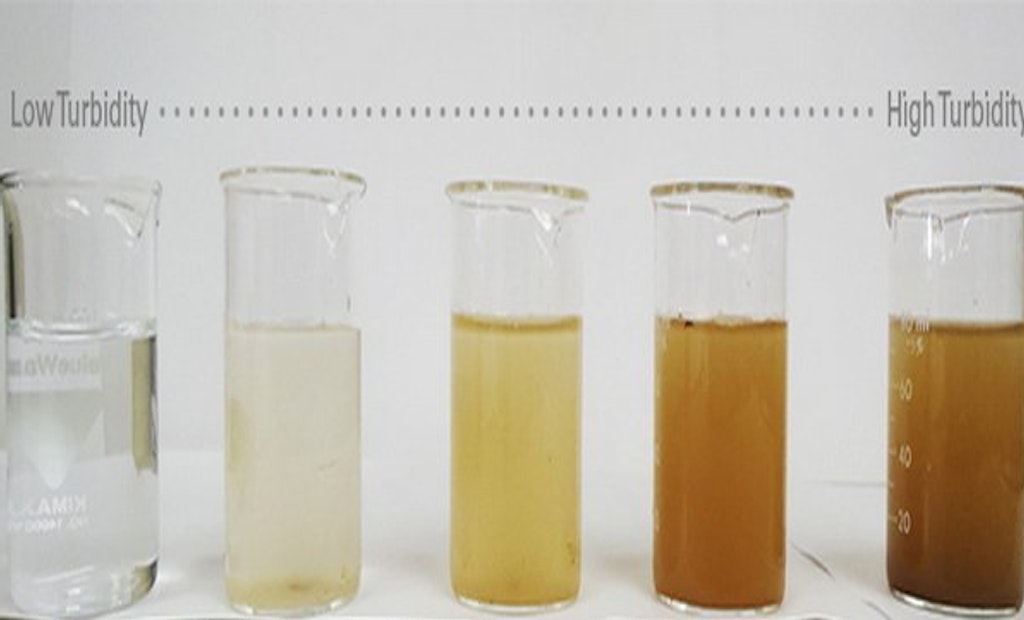

.jpeg) TSS (as stated earlier) is measured by performing a solids analysis, but it can also be estimated by a turbidity test. Turbidity is the physical clarity of the water and is an indicator of the presence of suspended matter in wastewater. A “quick and dirty” TSS test can be determined with an Imhoff cone. A visual test will determine if TSS levels are high or low when a sample of wastewater is placed in a cone against a light background.

TSS (as stated earlier) is measured by performing a solids analysis, but it can also be estimated by a turbidity test. Turbidity is the physical clarity of the water and is an indicator of the presence of suspended matter in wastewater. A “quick and dirty” TSS test can be determined with an Imhoff cone. A visual test will determine if TSS levels are high or low when a sample of wastewater is placed in a cone against a light background.

Impact of TSS on onsite system performance

High TSS can place a great demand on the downstream devices and could lead to clogged components and orifices in distribution manifolds. High TSS can result from several conditions:

- The system being underdesigned for the source supply.

- Use of low-flow fixtures: Although they conserve water, they do not reduce the constituent mass loading and result in higher concentrations.

- Use of a garbage disposal.

- Kitchen practices (e.g., kitchen cleanup, food preparation or type of cuisine).

- Above-average use of paper products.

- Laundry machines — due to clothing fibers, clay or soil present on the clothes. The volume of dirt and lint present in the laundry will directly relate to the habits, hobbies and occupation of the residents and the type of clothing they wear.

Low TSS is not a problem for the system, but it could indicate that something else is wrong with the system. Low TSS could be due to several conditions:

- Fewer users on the system than considered in the original design.

- Higher flows from low TSS sources.

- Clear water inflows.

Reducing TSS

Below are a range of options to reduce and manage the TSS in a system, which will help to promote system longevity.

- Reduce the amount of TSS from the source. This could include reducing or eliminating the use of a garbage disposal, installing a lint filter and overall reducing the amount of solids in the system.

- Limit antibacterial products (which can reduce the anaerobic decomposing of solids) entering the system.

- Limit products that may cause emulsification of the septic tank, such as degreasers and liquid fabric softeners.

- Spread out usage so septic tank velocity is as slow as possible.

- Install larger compartmented septic tanks that are not low profile to increase the amount of time for settling. The septic tank is a gravitational settling device that provides a space for sedimentation and flotation to take place.

- Install an effluent screen to hold back solids.

- Assure that septic tanks are pumped when more than 25 percent of capacity is storing sludge and scum.

- Install a secondary treatment unit, such as an aerobic treatment unit or media filter.

- Use pressure distribution in the soil treatment to spread out the organic loading.

- Install a soil treatment system with the ability to rest a portion of the soil treatment system.

About the author

Sara Heger, Ph.D., is an engineer, researcher and instructor in the Onsite Sewage Treatment Program in the Water Resources Center at the University of Minnesota. She presents at many local and national training events regarding the design, installation and management of septic systems and related research. Heger is education chair of the Minnesota Onsite Wastewater Association and the National Onsite Wastewater Recycling Association, and she serves on the NSF International Committee on Wastewater Treatment Systems. Ask Heger questions about septic system maintenance and operation by sending an email to kim.peterson@colepublishing.com.

This article is part of the series: An Installer's Guide to Wastewater Characteristics

- The Installer’s Guide to BOD5

- An Installer’s Guide to Total Suspended Solids

- An Installer’s Guide to COD

- An Installer’s Guide to FOG

- An Installer’s Guide to Phosphorus

- An Installer’s Guide to Wastewater Pathogens

- An Installer’s Guide to Nitrogen