TSE (treated sanitary effluent) Treatment room includes Grundfos pumps (left) that convey treated water from a storage tank to toilets throughout the building for use in flushing.

When it received a grant of 388 acres of land about a decade ago, Chatham University already had a main campus near downtown Pittsburgh and another about a mile east of the main campus. The university’s leaders decided to use a fraction of the newly acquired land for a third campus about 25 miles north of downtown. This campus would combine the best of sustainable technologies including an integrated system to handle the water falling on and flowing through the campus.

How well they succeeded is shown by the award the project won: a COTE Top 10 Award from the Committee on the Environment of the American Institute of Architects. Each year the American Institute of Architects gives these recognitions to projects that set high standards in design and sustainability. Chatham University says the Eden Hall Campus is the first fully sustainable campus in higher education in the world.

The property came with some buildings that were remodeled. Four new environmentally advanced buildings were added to form the core of the campus. Those are: the Café, a former dairy barn; the Field Lab that houses the aquaculture program, a classroom laboratory, and the controls for the wastewater system; the Esther Barazzone Center that has the main campus kitchen, student activities center, and classrooms; and South Orchard Hall, a residence building for 66 people. The Café, Barazzone Center, and Orchard Hall also have solar photovoltaic arrays with a combined output of just over 200 kilowatts.

The campus is still under development, says John Cunningham, director of facilities and building systems. There is a 50-year master plan that foresees several more buildings, and the plan also dictates how water is handled. The campus has an integrated system that accounts for everything from rainwater to wastewater.

WATER STAYS ON CAMPUS

Rain flowing across the ground is collected in about 19 rain gardens and subsequently flows into local streams. Roof runoff is collected in a 50,000-gallon storage tank and can be used for irrigating landscaping and gardens. At the moment, most of the stored rainwater overflows the storage tank and returns to local streams, but this capacity will allow for more irrigation as the campus develops, Cunningham says.

“Our main parking spot is a graveled area,” Cunningham says. “There is an adhesive layer to keep the gravel in place, but it is a permeable surface. Very little of this campus is paved with anything.”

Almost all of the wastewater processed on campus stays on campus. The exception is Orchard Hall. Recycled water is used to flush toilets there, but that blackwater flows into a municipal sewer system. Yet that is only about 10 percent of the wastewater produced on campus. The other 90 percent is handled by the recycling system.

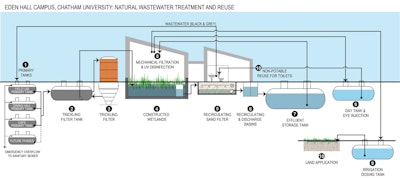

The Café and Field Lab each have a 1,500-gallon septic tank for initial treatment. The Barazzone Center has a 10,000-gallon tank to handle the greater flow from the kitchen and student center.

From these tanks, water flows into a 4,000-gallon tank that has one compartment with a trickling filter and a second that equalizes flow from the filter compartment and doses 3,600 square feet of constructed wetlands. Water next flows into a recirculating sand filter and then into a storage tank.

VARIABLE FLOW CHALLENGES

Water from the storage tank can be reused for flushing toilets or land application through dripline in two forested areas and one grassland. (Rainwater is used to irrigate landscaping.) But first the water passes through a pair of filters, 100 micron (Orival Water Filters) and 5 micron (Pentair Industrial), and then past UV lamps (Atlantic Ultraviolet). A turbidimeter from HF scientific set to a limit of 10 NTU governs where the water flows. Water reading less than 10 is released for nonpotable use in buildings. Water reading greater than 10 is diverted to the irrigation dose tank. Any excess water from the reuse tank also flows to the irrigation dosing tank.

Panels controlling the system were all custom-made by Orenco Systems. They run on solar power and convert the DC current into low-voltage AC to run the electronics.

“One of the big challenges in doing this system was the soil. We had a lot of trouble finding soils suitable for land application,” says Ryan Case of Biohabitats in Santa Fe, New Mexico. His company was contracted to design the campus water management system.

How much water is reused in buildings varies with what is occurring on campus, Cunningham says. On a low-use day, the system processes about 1,000 gallons. On a really busy day when there are events on campus, the flow is a couple thousand gallons.

“That flow variability is one of the challenges we have now in operating the system. As the campus activity has picked up during the last couple of years, the flow has increased. My bigger problem is I’m always dealing with after-the-fact knowledge of what’s going on as opposed to being able to predict what will happen if there is an event with 500 people,” he says.

He and Nicole Weiers, the certified wastewater operator who runs the system, have been working on pump averages to try and get a handle on this.

“There is a lot of flow variability,” Weiers says, “but the system is designed with enough redundancy to handle not only the changing flows, but also changing strengths.”

Influent BOD can vary from 60 to almost 400 mg/L. If BOD is still high coming out of the primary treatment tanks, the trickling filter is there to reduce it, and the wetlands can do more, and the sand filter can do still more, she says.

SYSTEM EVOLUTION

Each stage also has some equalization capacity, Case says. Override timers control each stage of the system, and these can be adjusted to alter the flow on days when there may be a large event or during semester breaks when there is little water use on campus.

“The choice of treatment was also part of this,” Case explains. “We use attached growth because we knew we would have a variable food supply for the bacteria, but in the wetlands and trickling filter, we have a habitat that sustains the bacteria and enables them to grow rapidly when needed.”

In the buildings with new construction, where purple pipes handle the recycled water, there is also an educational feature, Case says. Plexiglass panels are installed in the walls so students or visitors can see the purple pipe and build an understanding of the water system.

That is not to say the system has been problem-free. Some of the pipes were improperly laid, Cunningham says. They don’t drain well, and a couple have large dips in them. He had some cracked pipes in the winter of 2016-17 and attributes this to how the pipes were laid.

You could call these growing pains for a new system. Like the system, the campus is at the beginning of its life. Yet plans are in place to handle future wastewater needs. Preliminary design work is already done for the next planned expansion, Case says. Because of site constraints, there will have to be a second onsite treatment system for additional buildings, but the supply system for recycled water will tie into the system for new buildings.

In other words, if Chatham University is already an example of wise water use, it is prepared to remain an example for decades.