In States Snapshot, we visit with a member of a state, provincial or national trade association in the decentralized wastewater industry. This time, we learn about a member of the Wisconsin Liquid Waste Carriers Association.

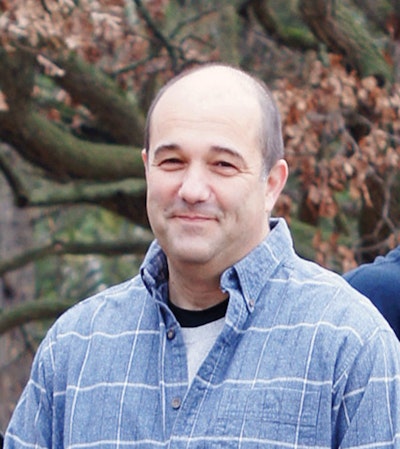

John Bowen, president

Business: Ken-Way Services of Rice Lake Inc.,

Rice Lake, Wisconsin

Age: 64

Years in the industry: 30

Association involvement:

The Wisconsin Liquid Waste Carriers Association was established in 1972. I joined in 1987 and three years later became president and served four years. I’ve been on the board for 20 years and two years ago became president again.

Benefits of belonging to the association:

I have very high regard for this association. It has helped me grow personally and has really helped our company grow into being a very respected professional business. There are many benefits. We have input on legislative rulings and code revisions involving our industry. We have upfront knowledge about what is in the works from the Wisconsin Department of Natural Resources and the U.S. Environmental Protection Agency. I feel we are more professional and profitable from the knowledge we gain from other pumpers. There are the friendships. Insurance is another thing — finding out where everyone is getting insurance. We have a couple conventions each year, which are well-attended. I cannot imagine not belonging to this association.

Biggest issue facing your association right now:

The Wisconsin Liquid Waste Carriers Association is a strong group with 140 out of 404 registered liquid waste businesses, but with many older member companies retiring or merging with other companies, we are having some difficulties recruiting new members.

Our crew includes:

My partner is my son, Cory. We have two full-time and two part-time office staff, eight full-time service technicians/drivers, and two part-time laborers.

Typical day on the job:

I usually start my day around 4 or 5 a.m., before all the other crew members come in, by hauling industrial liquid waste out of landfills or industrial plants. I like to start early to get a load or two out before everyone comes in. I then return to the shop to see the service technicians/drivers begin their day. I check in with my office staff to see if telephone calls need to be returned or if they have questions that need my attention. I then go out on service calls, which may include any or all of the following: clearing, jetting, and/or televising lines; septic- and holding tank-pumping; and portable toilet deliveries.

Helping hands – Indispensable crew member:

All our employees are valuable. There are two that stand out. One is my son, Cory, who grew up with the business and then after college graduation returned full time. I made him a partner so he can take over when I decide to retire. The other is our office manager, Cheryl Mlejnek, who has been with us for 18 years.

The job I’ll never forget:

Believe it or not, I have a very weak stomach and have been known to lose my “cookies” on certain jobs. I have to keep reminding myself of my motto: It smells like money! But one job I will never forget is when I was at the home of an elderly woman unplugging the line from the lift pump to the main sewer line. I had unhooked the pipe from the lift pump and was clearing the line. The homeowner was very interested in seeing what I was doing, so she was bent over behind me. She accidentally hit the float for the lift pump and got sewage all over her. Her final comment was, “I should know better than to watch what you are doing.” We both laughed.

My favorite piece of equipment:

Our five vacuum trucks because they are the bread and butter of our business — 2006 to 2017 Internationals with tanks ranging in size from 3,800 to 5,500 gallons from Imperial Industries (steel) and Advance Pump & Equipment (stainless steel), all with Wittig (Gardner Denver) pumps.

Most challenging site I’ve worked on:

We dredge a lot of sludge ponds for municipalities where we are floating on a barge in the pond and trying to remove sludge from the bottom. The challenge is to not take any more water than we have to, so you’ve got to keep the barge moving and maximize the amount of sludge being loaded into the vacuum trucks.

The craziest question I’ve been asked by a customer:

“Did you always dream of doing this job when you were growing up?” I have been asked that question by more than one customer.

If I could change one industry regulation, it would be:

I would like to see the pumpers able to gain larger volume of storage for the waste. We need to be able to store more gallons. The big issue in Wisconsin is getting enough sites to field-apply on. A lot of farms are cash-cropping now, and during the summer or in real wet conditions, a lot of pumpers don’t have a place to go. And especially in the northwest part of the state, the smaller pumpers don’t have treatment plants that can accept it so sometimes they have to put business off until they can field-apply it. It doesn’t make for a good relationship with their clients when they can’t give them emergency service. We’ve been working on that for a few years with the DNR, trying to get them to lighten up a little bit. Right now they’ve got what they call small storage where we can go up to 25,000 gallons. We’re trying to get that raised to a higher volume.

Best piece of small-business advice I’ve heard:

Some bits of advice I have received from many seasoned business owners and would like to pass on are: Do what you say you are going to do. Show up to the job at the time you told the customer you would be there. Always be positive to customers; negativity gains nothing.

If I wasn’t working in the wastewater industry, I would:

After high school graduation, I operated heavy equipment, then owned my own solid waste company and now a liquid waste business. Any of the above.

Crystal ball time – This is my outlook for the wastewater industry:

We have made big strides in attaining professionalism in our industry and I only see that continuing. We are all conscientious of protecting our environment for the future and I believe that will also continue.