Interested in Alarms/Controls?

Get Alarms/Controls articles, news and videos right in your inbox! Sign up now.

Alarms/Controls + Get AlertsTimed dosing configurations include an adjustable timer that controls pump rest interval and runtime to spread out the application of wastewater over time versus how it is generated in a home or facility.

Utilizing timed dosing instead of demand dosing mitigates variations or peaks in wastewater flow. Peak flows from the dwelling are stored and then dosed to subsequent components evenly throughout the day. Timed dosing configurations are more commonly found in systems that include advanced pretreatment devices or flow equalization.

Timed dosing is wise to consider for systems that will receive actual flows within 70 percent of design flow in order to ensure the system is not overloaded. Time dosing is also useful to detect leaks that can otherwise go unnoticed. All systems can benefit from time doses, as the naturally occurring microorganisms in the system prefer a more regular delivery of food. In addition, time dosing allows the soil treatment system to rest and re-aerate between doses that are uniformly applied.

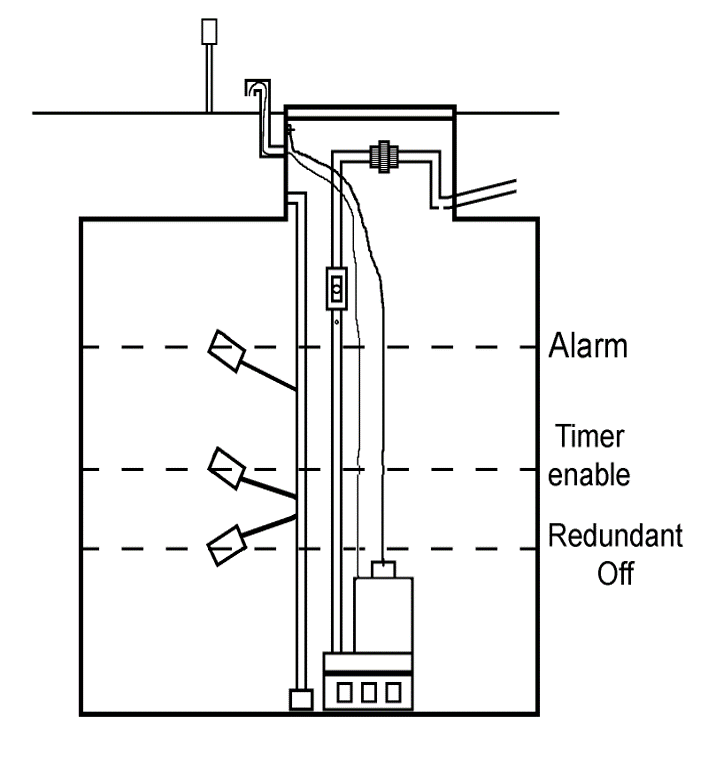

Timed dosing also uses floats to control operation. However, the float switch is a signal float instead of a motor-rated switch. When activated by the rising effluent level, the float sends the electrical signal to the control panel. The electrical signal enables the timer. After the prescribed rest interval, pump operation is initiated by a motor contactor in the control panel and the pump operates for a specified amount of time. The specified dose volume of effluent is delivered based upon the actual pump delivery rate. As with demand dosing, other devices such as pressure transducers and ultrasonic water level sensors may be used in lieu of floats.

Many different configurations are possible in timed dosing. One method includes a separate redundant off float. When this float is in the off position (indicating a low level of effluent in the tank), it protects the pump by not allowing it to operate, regardless of the pumping schedule set on the timer. Timer enable and redundant off function may be controlled by the same float.

Another option is a configuration that includes a peak enable float installed between the timer enable float and the alarm float. When activated during high-flow events, a peak enable float shortens the rest period between normal doses. As a result, more dosing events occur each day and reduce the effluent level in the tank more quickly. Peak enable and alarm function may be controlled by a single float. Note that systems that include peak enable floats are set so that forward flow does not exceed the capacity of the next component or the design flow of the system. Again, a cycle counter should be included to track the number of times the peak enable float is activated.

A timer override float is a differential switch that delivers a different volume to the next component. It essentially (and temporarily) changes the function of the timed dosed system to a demand-dosed regimen until the effluent in the tank is reduced to a normal operating level. These are not recommended because they can defeat the purpose of the timer system. If a timer override float is used, it is critical that a counter is included to track how often a timer override float is activated because this indicates how often the system has been hydraulically overloaded. Whether or not the float or sensor that operates the alarm is combined with other floats, the alarm should consist of an audible device and an easily visible light. It should be wired on an electrical circuit separate from the pump. Without a separate circuit, the pump can overload the circuit and the alarm will not operate.

Flow equalization

When effluent is pumped from one system component to another, there is an increased need for management. Flow equalization is a management concept that can help reduce stress on system performance due to high peak flows. In flow equalization, the peak flows are stored for a period of time to be delivered to the soil treatment unit over a longer period of time. Usually the flow for one day is equalized over a 24-hour period, but it can be done for longer periods of time, especially if peak flows last for longer than one full day.

For this to be accomplished, the tank must be large enough to handle these flows, and the pump operation should be controlled by a timer as opposed to a float. The pump tank capacity for a single-family residence using flow equalization should be at least two times the daily design flow. For nondomestic systems, there are three values that need to be calculated to determine storage requirements: design flow, required storage and a safety factor (20 to 30 percent). The sum of these values is used to determine the required capacity.

To use these values, real flow data (daily flow values) is necessary for the design of the system. The average flow is the calculated average for the daily flow reading for a certain time period. Typically, 45-90 days of data will give a clear idea of the use at the site. Regular events should be factored into the flow equalization design. One-off events can be dealt with using other methods of flow control such as portable toilets or pumping. The storage is calculated as the sum of the flows above the average that needs to be held in the system.

Time dosing installation

When a timer is being used to control the pump, the gallons per minute of the pump being used must be determined. In most instances, this will come from the pressure distribution design, but also may be chosen in gravity applications. During installation or on existing systems, the gallons per minute must be calculated by performing a drawdown test where the change in depth in a tank in inches is recorded over a period of time and multiplied by the gallons per inch of the tank. This is the only way to have an accurate dose.

- Timer On - To calculate the Timer On interval, the dose volume is divided by the gallons per minute of the pump. This will provide the number of minutes the pump will run each time it turns on. The pump will not activate if sufficient sewage is not present to be dosed.

- Timer Off - To determine the Timer Off interval take the number of minutes in a day (1,440) divided by the likely or typical doses per day and subtract the Timer On interval. This will establish the amount of time between doses in minutes. This off time may need to be adjusted over time if current usage per day is unknown.

- The Pump-Off float is set to cover the pump by taking the gallons to cover the pump and dividing by the gallons per inch of the tank.

- The alarm float is set to several inches above the Timer-On float.

About the author: Sara Heger, Ph.D., is an engineer, researcher and instructor in the Onsite Sewage Treatment Program in the Water Resources Center at the University of Minnesota. She presents at many local and national training events regarding the design, installation, and management of septic systems and related research. Heger is education chair of the Minnesota Onsite Wastewater Association and the National Onsite Wastewater Recycling Association, and she serves on the NSF International Committee on Wastewater Treatment Systems. Ask Heger questions about septic system maintenance and operation by sending an email to kim.peterson@colepublishing.com.