Interested in Pumps?

Get Pumps articles, news and videos right in your inbox! Sign up now.

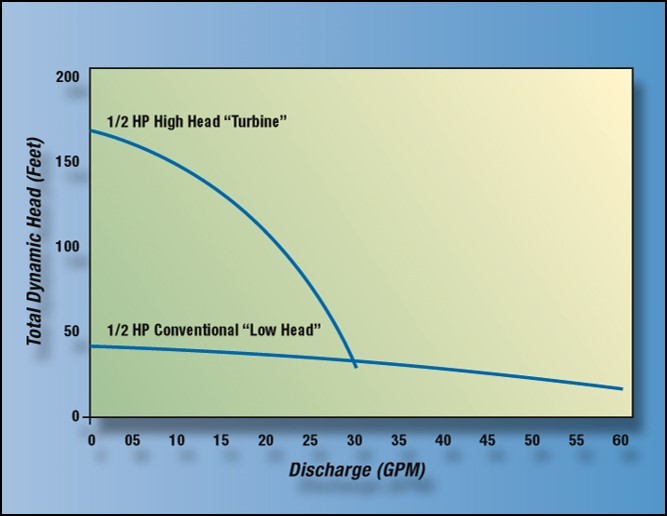

Pumps + Get AlertsThere are many types of pumps available to onsite system designers and engineers. Two commonly used pumps are the single-stage centrifugal pumps and screen turbine pumps. Typically, the decision between these two applications will focus on the head requirements of the system, but there are other items to consider. Regardless of the type of pump, an elapsed time meter and/or counter for pump troubleshooting and flow determination is recommended.

Single-Stage Centrifugal Effluent Pumps

Single-stage centrifugal pumps are the workhorses of most onsite septic systems in the United States that use a pump. This effluent pump’s purpose is to transfer pretreated liquid waste from an onsite sewage treatment device or system. Solids handling sizes of these effluent pumps are typically 1/2 inch in diameter. Typical pretreatment occurs in a septic tank, but they are often used after an effluent filter/screen or advanced treatment unit. Although they can handle smaller solids, the effluent quality of these pumps will be improved if filtered or placed in a pump vault. It is recommended that these pumps' float controls be mounted on a tree so floats can be easily adjusted and allow for ease in maintenance.

Advantages

- Lower upfront cost.

- Low maintenance requirements.

- Familiarity with the technology across the onsite industry.

- Pumps and parts are readily available and easy to service or replace.

- In some jurisdictions, pump replacement may be easier if a plug-in connection is used. In general, this practice is not recommended, as hard-wiring the pump creates a better connection and a panel for management.

- Can handle small solids (approximately 1/2 inch).

- Operate at higher flow rates (gallons per minute).

Disadvantages

- Residential units are designed to operate when there are low head requirements.

- If no effluent filter/screen is used or an overflow occurs, the pump will not be protected from solids or nonbiodegradables.

- These pumps wear over time, and with each passing year, head requirements may not be met.

Multi-Stage Turbine Pumps

Common applications for turbine effluent pumps include septic tank effluent pressure applications, effluent sewer force mains, treatment systems, and dripfield dosing. A turbine pump’s goal is the transfer or removal of natural or artificial pretreated liquid waste discharge from an onsite sewage treatment device or filtered STEP system. Solids-handling sizes of turbine pumps are less than 1/8 inch in diameter. They are almost exclusive packaged with a screened pump vault, as they cannot handle solids.

Advantages

- Operate well when there are higher head read requirements typically at lower flow rates.

- Very reliable as these pumps were developed and improved in the well industry before utilization in the septic industry.

- In systems using a pump for uniform pressure distribution, the pump will create significant additional head should the orifices begin to clog.

- Due to the requirement of a screen/filter prior to the pump, the pump delivers a higher quality effluent.

Disadvantages

- For large pressure distribution applications, these pumps may not have enough gallons per minute to meet system design requirements.

- Higher upfront cost.

- Annual maintenance.

- Most applications require hard-wiring and a panel.

- Must be filtered prior — cannot handle solids larger than approximately 1/8 inch.

- If no effluent filter/screen is used, the pump will need frequent cleaning (at minimum every six months); therefore this practice is not recommended.

In the design selection of a pump, many factors should be considered including the gallons per minute and head requirements, but also effluent quality, service, and longevity.

About the author: Sara Heger, Ph.D., is an engineer, researcher and instructor in the Onsite Sewage Treatment Program in the Water Resources Center at the University of Minnesota. She presents at many local and national training events regarding the design, installation, and management of septic systems and related research. Heger is education chair of the Minnesota Onsite Wastewater Association and the National Onsite Wastewater Recycling Association, and she serves on the NSF International Committee on Wastewater Treatment Systems. Ask Heger questions about septic system maintenance and operation by sending an email to kim.peterson@colepublishing.com.