Interested in Education/Training?

Get Education/Training articles, news and videos right in your inbox! Sign up now.

Education/Training + Get AlertsWe get a lot of questions about clean sand. Most are related to the clean sand requirement for mound sewage treatment systems. However, we do get questions about using sand in either single- or multiple-pass sand filters and use of sand or other materials as fill or final cover for soil treatment systems.

In this column, we focus on clean sand for mound treatment systems. In Minnesota, there are more than 50,000 mounds in operation. When designed and installed correctly, these are effective and long-lasting systems. Some have been in continuous operation since the 1970s. This type of success requires use of proper materials — clean sand and clean rock being the most important. One of the biggest problems we have seen when troubleshooting failing mounds is use of sand that is not clean, resulting in premature failures.

Sand performs two functions in mound systems: It provides initial treatment of sewage tank effluent and acts to disperse the partially treated effluent over the soil treatment area for final treatment in natural soil. To provide these functions requires sand free of silt and clay-size particles, which can — over time — wash through the sand to the soil infiltrative surface, forming a restrictive layer and reducing movement of water into and through the natural soil.

Since the installation of the first mound systems in the early 1970s, the definition of clean sand changed as more was learned about which systems operated best and for the longest times. The first definition merely said that the percentage of sand needed to be at least 90%, leaving the possibility to have as much as 10% “fines” (silt and clay-sized particles). Later research led to the recommendation to allow only 5% fines and that less than 5% was better.

SAND STATS

The definition we use in Minnesota is “clean sand is a soil texture composed by weight of at least 25% very coarse, coarse and medium sand varying in size from 2.0 to 0.25 millimeters, less than 50% fine or very fine sand ranging in size between 0.25 and 0.05 millimeters and no more than 5% smaller than 0.05 millimeters.”

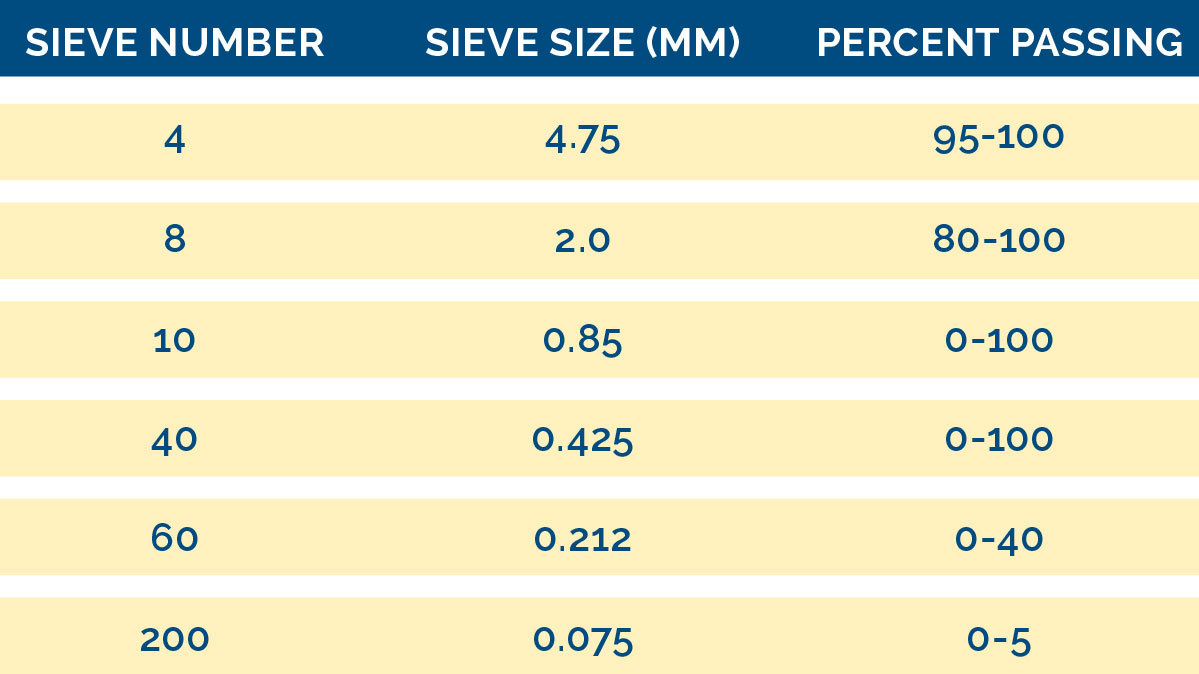

Clean sand according to the Minnesota code is defined by the following sieve sizes and percent passing each sieve.

A couple of points must be made. This definition is specific, so a “clean sand” fitting all of these criteria is difficult to find in nature; therefore, pit run sand, in most cases, will not meet the fines requirement, meaning the sand must be washed and sieved to achieve similar specifications. This increases the cost of the sand significantly, especially in areas where mounds are not built very often, so the volume of material with these specifications is low.

Our definition also includes a restriction on very fine and fine sands. This is because we have found through experience and research that these particles are very close in size to silt particles. If the percentage is too high, even though the material fits the sand size criteria, the soil will act more like silt in terms of permeability when septic tank effluent is added. When infiltration rates are reduced, a more resistant biomat can form at the infiltration surface, leading to mound failure.

WHAT ABOUT C33?

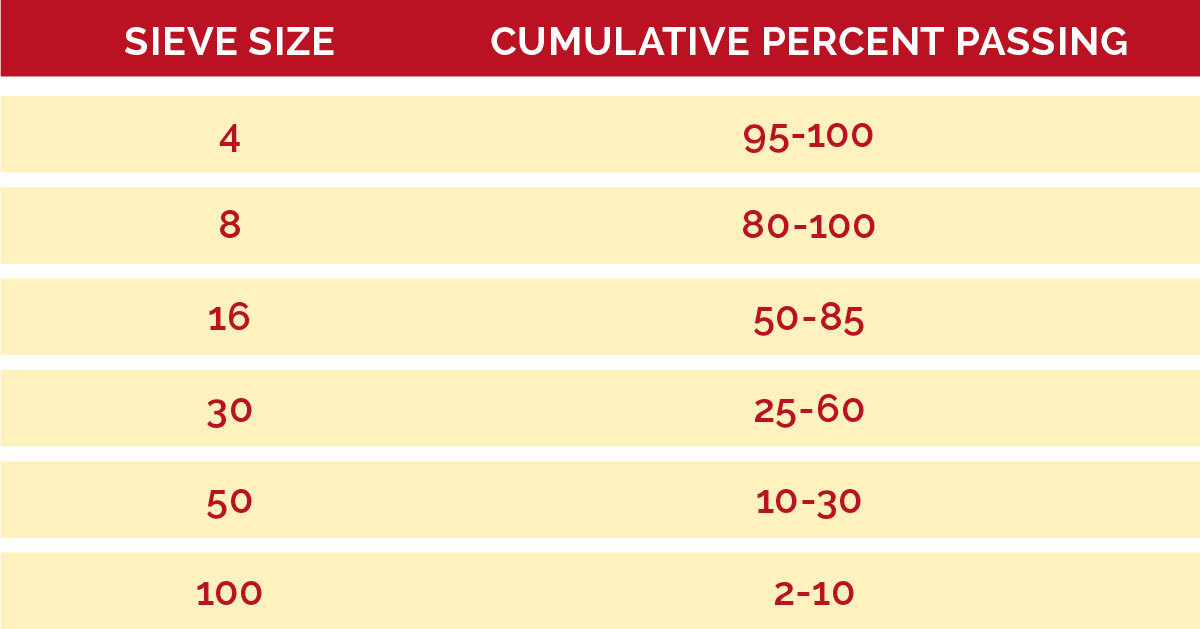

Because of the difficulty obtaining clean sand with these characteristics, some states have specified use of C33 sand as defined by the American Society for Testing and Materials. This is a material used in road construction and is widely available from suppliers. The problem is material meeting this standard can be variable. On the coarse end of what is allowed, the particles are larger and the percentages of fines are quite low, about 2%. This material certainly meets the definition of clean sand. At the lower end, the material could contain as much as 10% fines. When selecting sand, it is important to receive and look at the sieve analysis for the material purchased, because all C33 material is not the same.

To demonstrate differences in materials, below is the C33 sieve analysis to compare with the Minnesota definition.

Along with the sieve analysis, the supplier can provide a uniformity coefficient for the material. This tells how well-graded the material is: whether there is a wide range of sizes in the material or whether the material consists of mostly one size of particle. A uniformity coefficient of 1.00 means all the particles are the same size, while numbers larger than 1.00 indicate materials with less uniformity.

Have you solved a tough septic system issue with a creative solution?

Share your unique story with 18,000 other professionals. Send a note to editor@onsiteinstaller.com