More than 30 volunteers, contractors and industry suppliers donated time, equipment and materials to construct the onsite system for the Susan and Jack Davis Nature Pavilion. (Photos courtesy of Stephens Consulting Services)

The Fenner Conservancy wanted to build an addition for expanded programming at the Fenner Nature Center in Lansing, Michigan.

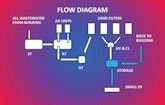

An onsite system served the environmental educational facility and organizers wanted the same for the Susan and Jack Davis Nature Pavilion. On...