This article is part of a series focusing on new technology available to monitor septic system performance. As technology continues to evolve and costs come down, these tools provide more in-depth information to be considered by designers, regulators, installers and service providers. The first system we will investigate is PointWatch.

The PointWatch system is a remote monitoring and control framework designed to integrate multiple sensors, analog or digital, and report them back to the PointWatch online portal for alarm monitoring, processing, and control. The results are available instantly or can be referenced later. User-customized notifications are provided via text, email and/or phone call. Instantaneous online graphs and charts are available for both recent and historical data accessible from a computer or smartphone. The communications between the control panel at the site and the PointWatch cloud-based portal uses the internet and can connect via hard-wired Ethernet, Wi-Fi or cellular data. There is a solar package for remotely powering devices when power wiring is a challenge.

Key features of the system:

1. It can incorporate any sensor.

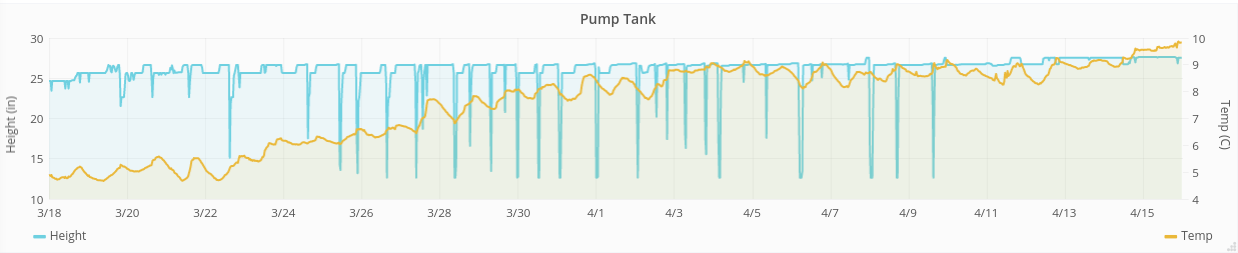

2. It provides system performance data: The graph below shows the soil temperature and increased pumping frequency versus normal for the system during spring thaw. This helped the service provider find a leaking riser.

3. It can be retrofitted into existing systems or be installed at time of construction.

A gravity flow distribution box where backup occurred. After cleaning and installing a monitored liquid level sensor, clogs are detected — thus preventing future backups.

4. PointWatch works for a wide range of system types — from a gravity system to a complicated denitrification system. The following are some specific examples of varying system complexity:

- A holding tank sensor to track liquid levels indicating when pumping is needed and if surface or groundwater leaks are an issue.

- A sensor for gravity septic systems that tracks liquid level to the inch and temperatures in the tank(s), distribution box, drop box(es), and in the trenches or bed.

- Pump monitoring, which includes amperage, length of each pump event, cumulative run time and monitoring seasonal high water. Any number of pumps can be monitored, whether demand, timer controlled, or alternating. Remote pump control can be used to adjust pumping frequency when conditions allow — such as pumping higher volumes during dry and hot daytime conditions and reducing overnight pumping when there is less evapotranspiration.

- Advanced treatment system monitoring adds additional information, such as amperage of aerator or blower motors, and sensor data for turbidity, dissolved oxygen, etc. Such information allows service providers to make operational changes remotely to assure proper treatment and permit compliance.

The system provides early detection of problem conditions, allowing service providers to schedule proactive maintenance and repairs before emergencies arise. It identifies causes, not just symptoms, thereby minimizing troubleshooting time. It is used to monitor permit compliance and streamline year-end reporting. The PointWatch system is another tool in the septic industry toolbox for monitoring system performance and problem prevention.

About the Author

Sara Heger, Ph.D., is an engineer, researcher and instructor in the Onsite Sewage Treatment Program in the Water Resources Center at the University of Minnesota. She presents at many local and national training events regarding the design, installation and management of septic systems and related research. Heger is education chair of the Minnesota Onsite Wastewater Association (MOWA) and the National Onsite Wastewater Recycling Association (NOWRA), and serves on the NSF International Committee on Wastewater Treatment Systems. Send her questions about septic system maintenance and operation by email to kim.peterson@colepublishing.com.

This article is part of a series on monitoring technology:

- New Methods for System Monitoring: Part 2

- New Methods for System Monitoring: Part 1

- New Methods for System Monitoring: Part 3

- New Methods for System Monitoring: Part 4