Since its founding in 1946, Camp Luther, located on 212 acres near Three Lakes, Wisconsin, has been the Camp of the North Wisconsin District LCMS (Lutheran Church Missouri Synod). As part of the mission – “Building up all people in Christ for service and witness to the world.” – a 10-week summer program will have up to 250 youth and 15 families staying in cottages daily as part of the Family Camp Program.

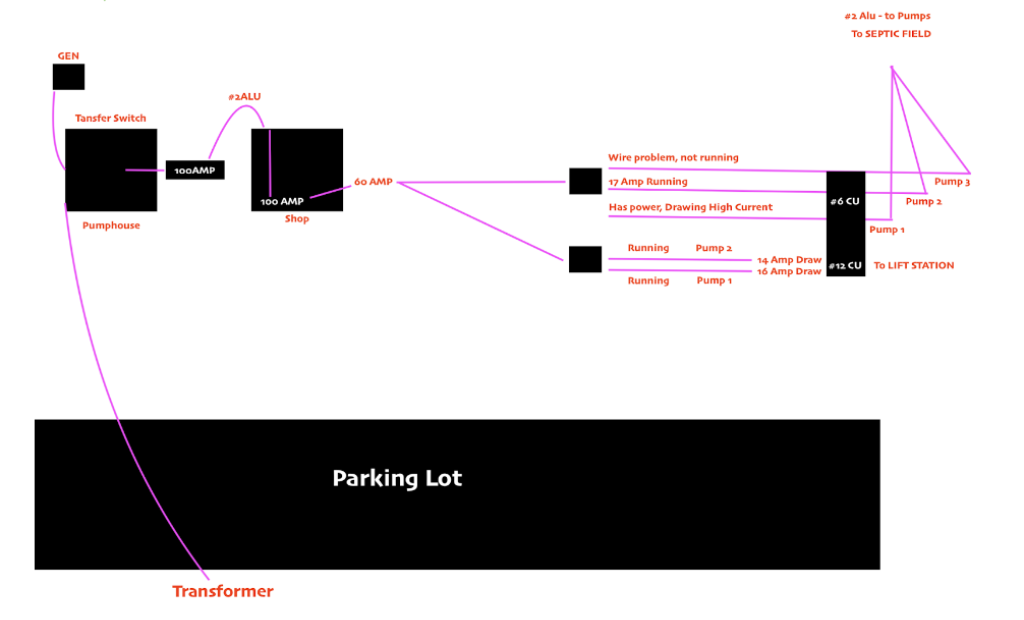

To serve all those campers, the camp requires a significant septic system. The system currently serves 22 of the 67 buildings on the property. The flow from the buildings runs into a single 11,713-gallon lift station with two grinder pumps that run in rotation.

Wastewater then flows to a 30,000-gallon poured-in-place tank (61 feet long, 14 feet wide and 8 feet high) that is separated into three nearly equal chambers. The first two chambers are used for separating solids, fats, oils and grease, and clear effluent. The effluent moves into the third chamber – a dosing tank – and is conveyed to the drainfield by three pumps.

The drainfield is made up of three beds that are 15 feet wide and 268 feet long, totaling 36,180 square feet.

Maintenance includes pumping 20,000 gallons of septage every May before the next camping season begins.

The nearly 40-year-old system – one of the largest in a two-county area – requires many component updates with an estimated cost of $175,000. The camp is currently fundraising to pay for the upgrades. The camp also has a long-range goal to add four cottages with 12 bedrooms to serve more campers.

Xylem from Milwaukee has been contracted to maintain the septic system for many years. They pull the pumps annually for pump maintenance and check the mechanical components for the system.

Two years ago the system started having wiring issues at the termination points of the pumps. Wires were breaking and losing power to the system. Just this year Xylem said they couldn’t complete the annual service with the pumps not receiving power and were even afraid to touch the wiring system in fear they would break more wires.

The scope of the job will entail:

- Two new grinder pumps that are three phase wiring

- Three new field pumps that are three phase wiring

- New floats and alarm components

- New rail system that the pumps slide on for removal and maintenance

- New control box at the field station

- New control box for lift station

- New monitoring station at base camp (shop)

- New wiring from the shop to control boxes

- New stainless steel lids and covers

- New Scada control monitoring system

The camp made an informational video released on Giving Tuesday, Nov. 28, to let its supporters and the public know about its need to repair this system. The video follows the decentralized treatment process to explain the complexities of the system for the layman and the many issues forcing these updates.

Companies serving the onsite industry who have questions about the upgrades or would like to contribute to the project can contact Brian Scheid, director of facilities, at 715-546-3647 or visit www.campluther.com.