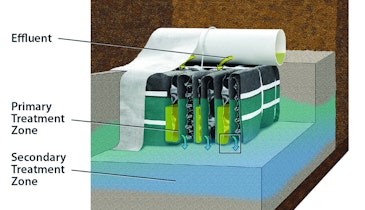

BioMicrobics’ specialized High Strength BioBarrier Winery assembly (pictured) is a preengineered membrane bioreactor system for boutique wineries. The winery system comes with membrane assemblies, controls and a BioRobic aeration system designed specifically for high organic loads associated with winery process waste.High Strength BioBarrier Winery is designed for flows of 1,500 to 9,000 gpd.

The MBR module is submerged in a tank full of aerated mixed liquor suspended solids, where the biological degradation of organic matter and suspended solids takes place. The ultrafiltration membranes filter out particles smaller than 0.1 microns, leaving the suspended biomass material — including disease-causing organisms — in the aeration tank. Robust aeration from the remote blower scours the surfaces of the membranes and provides oxygen to aerobic microbes; the High Strength BioBarrier Winery system uses additional aeration grids for high BOD concentrations. The resulting effluent is 99% free of contaminants such as BOD, TSS and fecal coliform. Depending on the design of the system, a high level of nitrogen and phosphorus can be removed as well.

BioBarrier holds NSF certifications for nitrogen reduction (NSF 245) and water reuse (NSF 350). The high-quality effluent drastically diminishes the drainfield size requirements, saving space and lowering construction costs. Depending on local regulations, the effluent may be able to be used for irrigation, dust settling and flushing toilets.

With more than 80,000 wastewater treatment systems installed in over 80 countries, we assist clients with providing more options and high-performance technology to meet and exceed regulatory compliance and end goals for water quality, including water reuse opportunities.

800-753-3278 | sales@biomicrobics.com | www.biomicrobics.com