Interested in Systems/ATUs?

Get Systems/ATUs articles, news and videos right in your inbox! Sign up now.

Systems/ATUs + Get AlertsWhy?

The surface should be maintained in as natural condition as possible because soils that are wet at the time of construction are more likely to have problems with acceptance of wastewater due to compaction and smearing. Compaction is the compression of soil particles, which closes the pore spaces. Smearing is spreading and smoothing soil particles by sliding pressure. If considerable construction activity has caused smearing or compaction, then the ability of the soil to transmit liquid will be seriously reduced and failure is more likely. Plastic limit is defined as the minimum water content at which the mixture acts as a plastic solid and is easily checked in the field.

When?

Compaction and smearing are more likely to occur with installations on sites with wet soils and high water tables with soil textures with higher silt and clay content. Any texture finer than a sandy loam can be smeared if the soil is wet enough.

The higher the clay content of the soil, the greater the likelihood that the soil will hold water. Soils that are saturated, meaning all the pore spaces are filled with water, or nearly saturated have lower soil strength, and they will compact and smear more than the same soil under dry conditions. If the soil contains expansive clays, such as smectite, the soil will also begin to swell.

To limit impacts to the natural soil structure, excavation is only allowable when the soil is below the plastic limit and when the soil is therefore dry enough to be worked. Soils at or near the plastic limit will be significantly altered by normal construction activities (e.g., traffic, excavation, building, etc.). The alteration can render a soil that was suitable for a subsurface sewage treatment system into one that will no longer support an SSTS. To assess the soil’s ability to suitably withstand the construction activities at the current soil moisture status, the below procedure should be followed.

How?

The plastic limit field test is a field check of the soil moisture content below which the soil may be manipulated for purposes of installing the soil treatment area and above which manipulation may cause smearing and compaction. The procedure to follow to perform the field test is as follows:

1. Select a handful of soil for testing. Any non-soil material, rocks and debris should be removed. Do not add moisture or let the sample dry out. Sample should be taken where wastewater will enter the soil and excavation equipment will be digging. The depth at which the test is run depends on the type of system being installed. For below-grade systems, the sample should be taken at the infiltrative surface where effluent will leave the media and enter the soil. For drip distribution systems this should be performed at the depth of bury. In an above-grade system, such as a mound or at-grade system, the soil should be tested at the surface and to the depth of scarification.

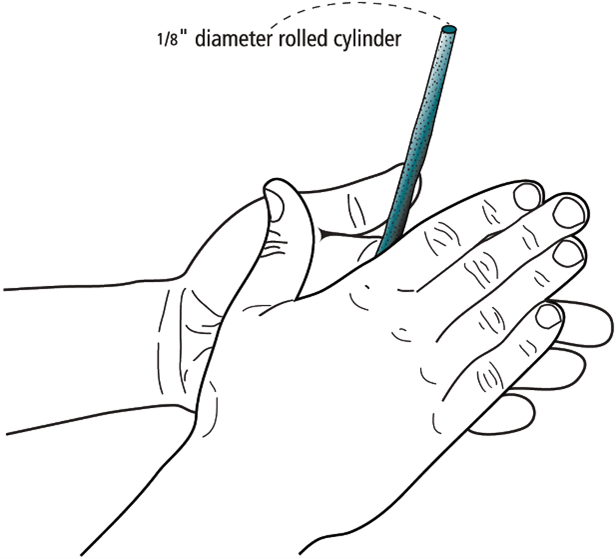

2. Roll the sample between the palms in the shape of a pencil.

3. Continue rolling the thread until it reaches a uniform diameter of 1/8 inch if possible.

4. If the sample does not reach a diameter of 1/8 inch the soil is friable (crumbles easily). The soil moisture content is below the plastic limit and construction can proceed.

5. If a fragment of soil can easily be rolled into a wire 1/8-inch in diameter, as show in the figure, the moisture content is above the plastic limit and you must wait for the soil treatment area to dry out before you proceed.

Following these procedures when constructing soil treatment areas will help to assure the system is a long-term solution for the property owners, public health and the environment.

About the author

Sara Heger, Ph.D., is a researcher and educator in the Onsite Sewage Treatment Program in the Water Resources Center at the University of Minnesota, where she also earned her degrees in agricultural and biosystems engineering and water resource science. She presents at many local and national training events regarding the design, installation and management of septic systems and related research. Heger is the President of the National Onsite Wastewater Recycling Association and she serves on the NSF International Committee on Wastewater Treatment Systems. Ask Heger questions about septic system design, installation, maintenance and operation by sending an email to kim.peterson@colepublishing.com.