There are many reasons to use an aerobic treatment unit when selecting an onsite system design, including poor soils, shallow vertical separation distances to limiting conditions, horizontal setback restrictions, tight lots, high-strength wastewater, and nitrogen treatment.

The treatment process utilized in ATUs is all about providing a suitable environment for microorganisms to treat the wastewater. Mechanically induced aeration is used to keep an oxygen concentration of about 2 mg/L or 2 ppm and provide mixing within the unit. The oxygen and mixing will allow the microorganisms to break down the organic portion of the waste. In addition, mechanisms must be employed to keep solids out of the effluent and bacteria returning to the treatment process. The resulting effluent produced from an ATU is higher quality than that from a septic tank in terms of total suspended solids, biochemical oxygen demand, ammonia reduction, and in some instances, total nitrogen removal.

Aeration

There are a couple different ways to get oxygen into the wastewater. The amount of oxygen diffusion is dependent on the surface area of the air bubbles. Fine or small bubbles with the same total volume of air as coarse or larger bubbles have greater surface area and therefore are more efficient at getting the air into the water. In some cases, coarse-bubble diffusion is useful and can pay off in the long run, but it is not as efficient. When doing wastewater treatment calculations, an efficiency rating is applied according to the type of diffusion, to be sure the system is sized appropriately.

Treatment methods

There are several different methods in which microbes grow in ATUs. In suspended growth systems, the microorganisms are free floating in the aeration basin. Mixed liquor is the liquid in a reaction chamber of an ATU that contains the microbes and the wastewater. Mixed liquor suspended solids is a measure of the material floating in the reaction chamber, and it includes the microbe count plus any inorganic suspended materials in this chamber of an ATU. In a typical activated sludge system, a healthy MLSS is in the 3,000-6,000 mg/L range.

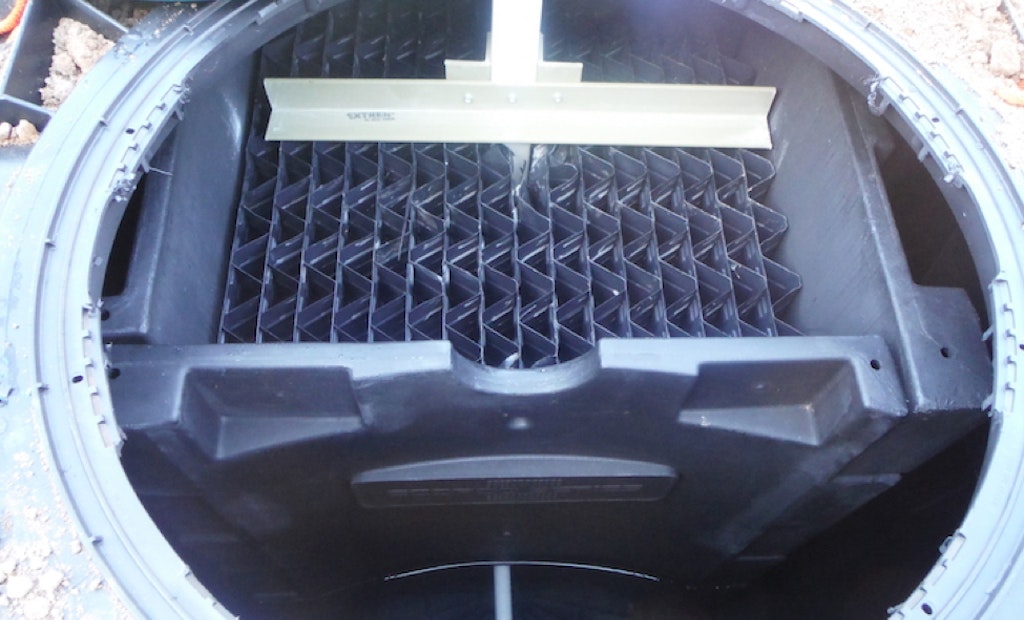

In a fixed or attached growth system, the microbes are attached to some sort of media and MLSS is not typically measured. The air entering the system assists in bringing the food to the microbes that are attached to the media and the submerged media allows the microbes to be attached in a saturated condition and grow. As the biofilm gets dense and heavy, it falls off the media and is replaced with new growth. These media are generally made of plastic or an inert material.

Membrane bioreactors, or MBRs, are relatively new to the industry. The treatment accomplished by this process is exceptional. The actual treatment method employed is suspended growth, and a membrane cassette or module is place directly into the MLSS. The effluent moves from the mixed liquor, which is outside the membranes, to a void space inside the membranes and out of the system for discharge. The membranes have such small holes in them that all the mixed liquor is maintained in the system. This results in an effluent that is very low in BOD5 and TSS, is disinfected, and often is almost completely nitrified.

Maintenance

All ATUs take more maintenance than their conventional counterparts. They have moving parts that need to be kept in good working order and other conditions that need to be maintained so the bacteria treating the wastewater is kept healthy. These systems also produce biological sludge as a byproduct of the treatment process. This sludge accumulates as bacteria grow and die in the treatment process and will need to be physically removed periodically to keep the system performing well. As the waste strength gets higher, the sludge accumulates even more quickly.

This article is part of a series on the design of aerobic treatment units.

- An Introduction to Designing ATU Systems

- Introduction to ATU Systems: Microbial Growth Requirements

- Introduction to ATUs: Creating a Sustainable Design