If a septic tank is operating properly, solids are retained and take up increasingly more volume. Eventually, they must be removed.

If there is little accumulation of solids, either the household has limited usage or there is a problem causing solids to pass through the tank. When there is little clear zone left, proper solids separation will no longer occur, detention time for settling is further reduced, and solids will wash out of the tank, eventually clogging the soil treatment area or downstream component and then causing system failure.

Research on solids accumulation shows the interval between pumping depends on tank size, number of people in the house and the nature of the sewage (which in turn depends on household habits and lifestyles). Many publications and maintenance programs recommend a three- to five-year pumpout interval. This interval is usually reasonable, but checking sludge levels at the time of service can provide a better estimate of the necessary pumpout interval.

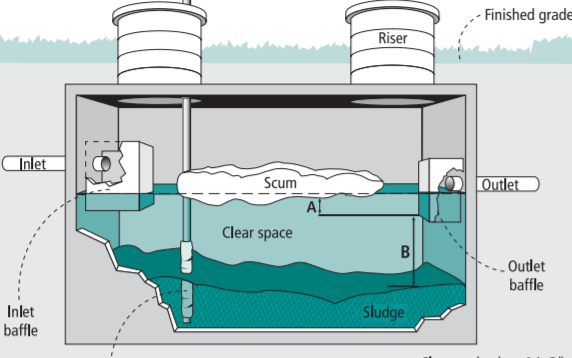

The most reliable method for determining the need to pump is regular inspection of the tank, including measurement of sludge and scum thickness. If we use regular inspection as a method for determining pumpout needs, a tank is “full” when the top of the sludge layer gets too close to the outlet baffle (B: approximately 12 inches) or when the bottom of the scum layer gets too close (A: approximately 3 inches). Another way to think of this is adding up the depth of sludge and scum and determining the proportion of the tank that is being used for storage of sludge and scum.

A typical guideline is pumping when scum and sludge levels reach 25% of tank liquid capacity. When evaluating two-compartment tanks or systems with two tanks in series, it is important to open and evaluate both of the compartments or tanks. Particularly with commercial systems, it is often not needed to clean all the compartments or tanks — just those that are close to or above 25%. If there is a recirculation, processing or pump tank in the system, these tanks should also be evaluated for buildup of sludge and scum.

Many devices can be used to both determine sludge and scum accumulations periodically or to monitor levels on a continuous basis. Proprietary devices are made of clear PVC pipe and are tools for measuring the sludge and thin scum. Devices can be constructed of a small paddle on a stick or an L-shaped rod for measuring thicker scum levels.

Pumping too frequently may prohibit the development of a normal population of beneficial microbes. From the perspective of system longevity, it may be best to err on the side of pumping too often rather than not enough; however, excessive pumping increases the burden on septage disposal facilities and adds unnecessary cost for the owner. In addition, there is some evidence that when tanks are pumped every year or even more frequently, they sometimes do not develop normal scum and sludge layers. Decision-making based on actual tank conditions observed during inspection is recommended.

Tanks that are not designed, installed and used correctly may float out of the ground when they are pumped during seasons of high groundwater or flooding. If a tank must be pumped under high groundwater conditions, consider placing a uniformly distributed static load over the tank until it can be refilled with water immediately after pumping. The static load should be sufficient to ballast the tank without causing structural damage. In addition, tanks may collapse from external soil pressure. This can be costly since the tank must be reexcavated and replaced. To prevent flotation or collapse, it is best to pump at a time during the year when the seasonal water table is below the tank.

When servicing septic systems, damaged tees and baffles are sometimes observed in older tanks. Concrete baffles and clay and concrete tees used as baffles may deteriorate in the moist, corrosive atmosphere of a tank. Deteriorated or missing baffles must be replaced as soon as the condition is discovered. This is usually done by replacing the original unit with a PVC or other plastic baffle tee. It is recommended that an effluent screen be added as part of any outlet baffle replacement operation. A failed outlet baffle can usually be replaced by inserting a section of 4-inch PVC into the outlet pipe and adding necessary fittings inside the tank to either use a 3-inch baffle tee or fit to a selected outlet screen. At the time of tank pumping or service, access risers and lids must be checked for leakage or any structural damage. Any leaks should be repaired or patched, but structural damage indicates the need for replacement.

About the author

Sara Heger, Ph.D., is an engineer, researcher and instructor in the Onsite Sewage Treatment Program in the Water Resources Center at the University of Minnesota. She presents at many local and national training events regarding the design, installation and management of septic systems and related research. Heger is education chair of the Minnesota Onsite Wastewater Association and the National Onsite Wastewater Recycling Association, and she serves on the NSF International Committee on Wastewater Treatment Systems. Ask Heger questions about septic system maintenance and operation by sending an email to kim.peterson@colepublishing.com.