Chloride levels in many surface waters are increasing and pose an emerging environmental concern since elevated chloride levels are harmful to aquatic life. Numerous communities across the U.S. have observed surface waters with chloride water-quality impairments, and chloride levels in groundwater are also increasing, particularly in urban areas.

A major source of chloride is water softening. In homes that have moderately to very hard water, many use water softeners. Water softeners remove minerals that cause scale buildup in pipes, appliances and water fixtures, and deposits on glassware. Ion-exchange water softeners use salt, usually sodium chloride, for recharging.

In cities, the salty recharge water (brine) drains to the sanitary sewer where it travels to a wastewater treatment plant. Unfortunately, it isn’t feasible for most wastewater treatment plants to remove chloride, which is dissolved in water. In areas served by septic systems the brine often discharges to the septic system, although this is not a recommended practice as large amounts of sodium chloride can be detrimental to the system.

Is a softener needed?

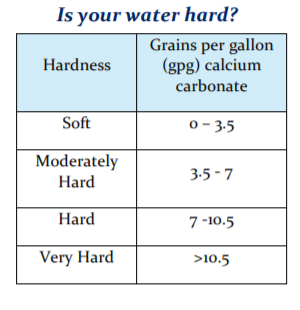

Hardness less than 5-7 grains per gallon (gpg) may be acceptable to many homeowners. If the drinking water is from a river, it is naturally softer and you probably don’t need a softener.

If water is publicly supplied, you can find your water hardness from the water utility or city. Some cities soften the water at the drinking water plant. Your customers can have their water tested by a professional or buy a kit and test it themselves.

Share these practices to reduce salt use and discharge from water softeners:

1. Consider upgrading the softener - Replace a timer-regenerated softener with a demand-initiated softener. High-efficiency features that can reduce salt-use feature:

- Efficiency rating of 4,000 grains per pound of salt or higher

- Upflow or counter-current regeneration

- Hardness sensors and water meters

- Variable reserve

- Regeneration with softened water

- Twin tanks.

2. Make sure the softener is sized correctly - Softeners that are too small or too large for household water use are less efficient.

3. Soften only as necessary - Soften only indoor-use hot water or soften specific appliances, such as water heaters.

4. Conserve water - Practice water conservation to reduce softener regeneration and salt use (e.g., using low-flush toilets, using high-efficiency or front-loading washing machines, taking shorter showers, etc.).

5. Regularly maintain the softener - Review the softener manual, check settings and have the system optimized by a professional.

6. Remove high iron from well water - High iron can clog the resin, so use a test kit or consult a professional to measure iron levels. If iron levels are greater than 3 ppm, consider installing an iron filter to increase efficiency and water softener life, although discharge should be diverted from septic systems.

7. Remove high chlorine from city water - Find out the chlorine level from your public water supply, since high chlorine can damage the resin. If chlorine is over 1 ppm, consider installing a chlorine filter to increase efficiency and water softener life.

About the author: Sara Heger, Ph.D., is an engineer, researcher and instructor in the Onsite Sewage Treatment Program in the Water Resources Center at the University of Minnesota. She presents at many local and national training events regarding the design, installation, and management of septic systems and related research. Heger is education chair of the Minnesota Onsite Wastewater Association and the National Onsite Wastewater Recycling Association, and she serves on the NSF International Committee on Wastewater Treatment Systems. Ask Heger questions about septic system maintenance and operation by sending an email to kim.peterson@colepublishing.com.